|

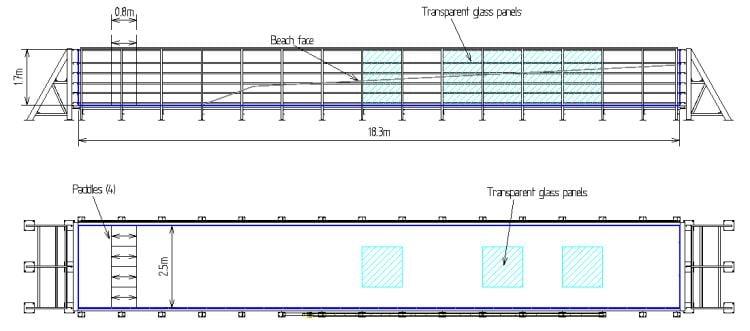

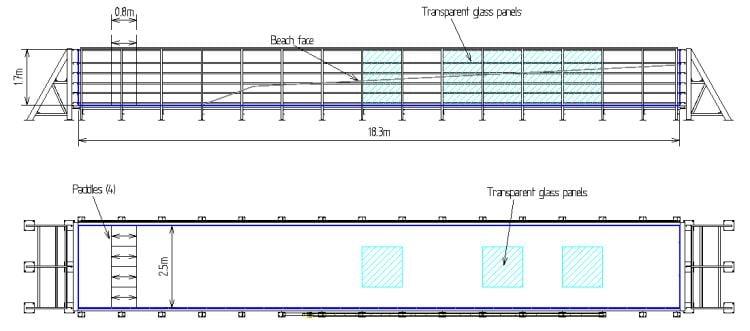

| TOP: Side-view of wave tank schematic. BOTTOM: Plan-view of wave tank schematic. |

|

| TOP: Side-view of wave tank schematic. BOTTOM: Plan-view of wave tank schematic. |

|

|

|

|

| All columns in place on west side of tank. | Placing a short beam with brute strength. |

|

|

| Lifting one of the small cross-channel beams over the tank. | Balancing one of the large cross-channel beams on the lift. |

|

|

| All beams and columns are in place. Tack welding a small beam. | Tacking the cross-bracing. |

|

|

| Don't look at the arc, you'll hurt your eyes. | Looking down from the far end of the tank. |

|

|

|

| 10/9/03: Pouring an elevated concrete pad for the hydraulic power units. | 12/1/03, 8:30 AM: Finished pad, all ready for placement of power units. | 12/1/03, 12:00 PM: Power units in place! |