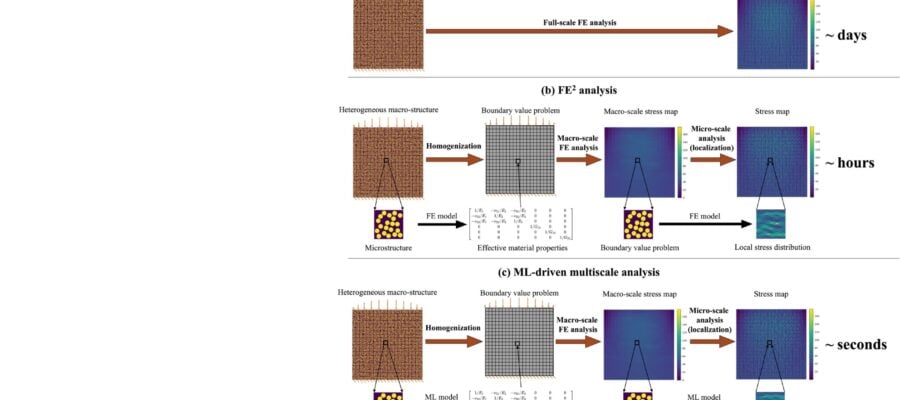

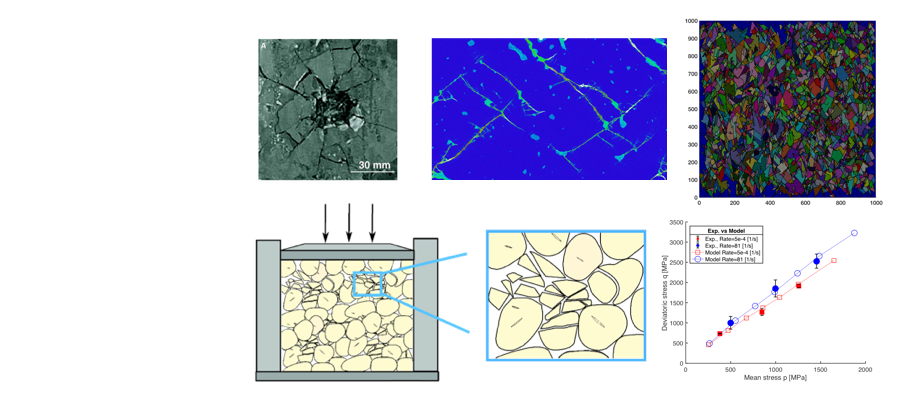

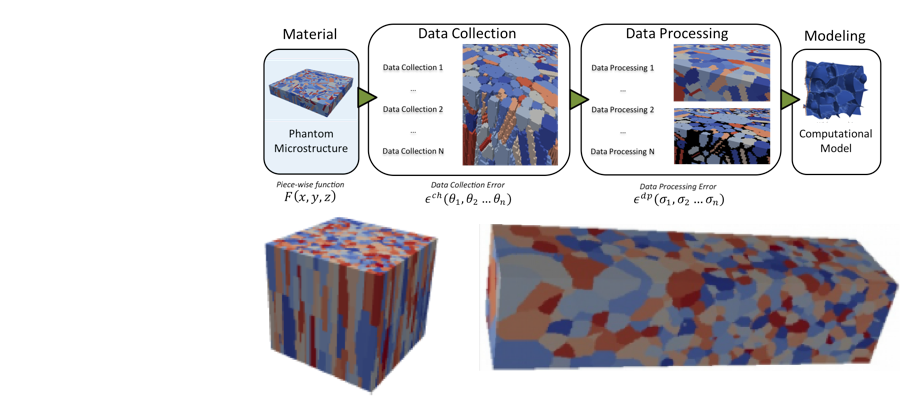

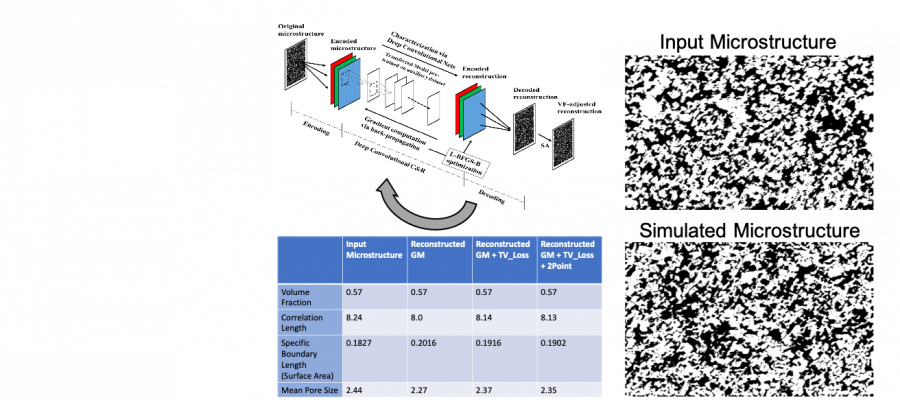

The Graham-Brady research group focuses on the problem of modeling the effects that material randomness has on structural performance. This material variability plays a key role in localizations that lead to large-scale structural failure. Our approaches include stochastic modeling, deep learning, transfer learning, and uncertainty quantification. Recent application areas include ceramics and concrete under high-rate loading, characterization error in high-strength metal alloys, composite materials under impact, and lightweight porous materials.